InGlove – Project Post #3

Curt, Shruthi, Vedant

Weekly Accomplishments

Curt

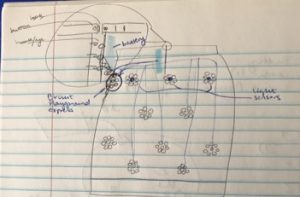

In the week before spring break I primarily worked on designing the robotic finger and experimenting with mounting locations for the finger. In the images section I will cover the limited prototype that I constructed to see if the mounting location made sense and a couple of screen captures of the current finger design. My next step is to focus on 3D printing the finger and to work on a custom flex sensor that can measure two joints in the glove. I also need to explore a mounting mechanism for the finger that is comfortable yet secure.

Vedant

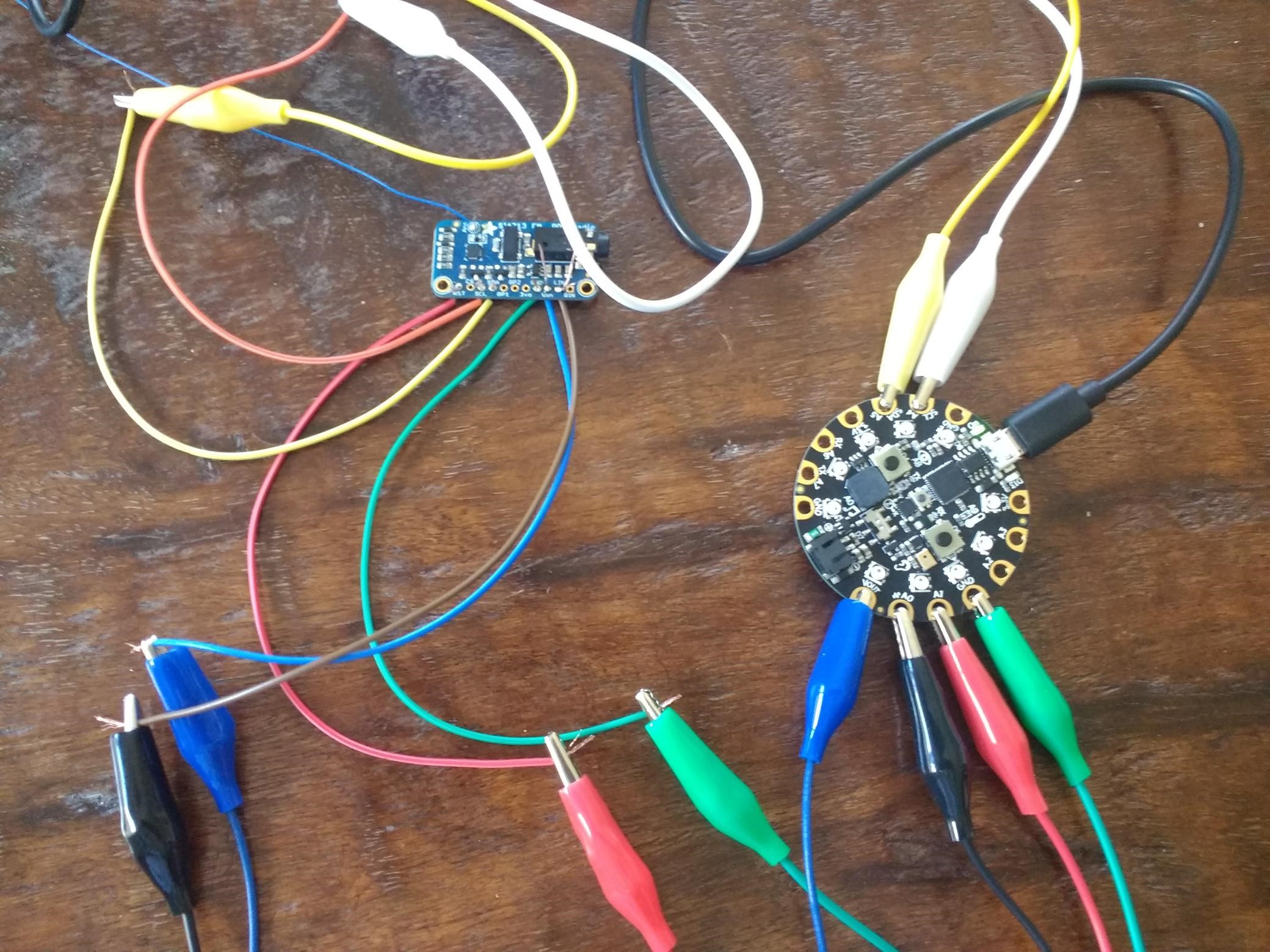

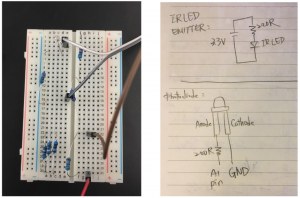

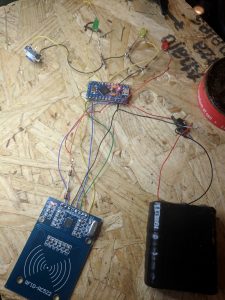

The week before spring break, we were able to make a DIY flex sensor using some duct tape, conductive thread and a few pieces of Velostat (pressure-sensitive fabric). We tested that out using a voltage divider circuit and got some promising results in the changing voltage. I was able to connect that voltage divider circuit with a Circuit Playground and use the serial plotter in the Arduino IDE and found that there actually wasn’t very much noise from the DIY flex sensor.

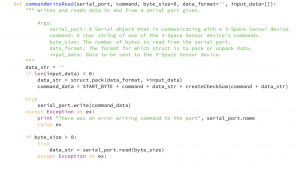

In addition to that, the Photon Particle and flex sensors came in, and we got stared with how to use the Particle and get started with some basic circuits connected to it and how to use the Particle cloud IDE. We were also trying to get some readings from the flex sensors on the Particle cloud over WiFi, but we were not being able to, so I helped diagnose the problem and found that one of the sensors we ordered was defective. However, trying the same code and circuit with the other sensor, we were able to get some promising readings.

Shruthi

Over the past week me and Vedanth worked together on trying out different kinds of flex sensors. We ordered a batch of long and short ones from adafruit as well as tried making one one our own using velostat and conductive threads. We built voltage divider circuits to measure the change in voltage drop with the varying resistance of the flex sensor. Both of us were fairly new to hardware debugging, but we eventually figured out that one of the flex sensors we ordered was defective. We were successfully able to get the readings on the other one. However, in this whole process we found that our DIY flex sensor had comparable results in flex detection as the store-bought one. We might consider using DIY sensors for the remaining fingers as they are more affordable.

Images

SRF Sub-Project

In Figures 1 and 2 I am presenting the physical mockup to get a sense of the hand and how the finger takes up space around it. The goal of this is to make the design process more concrete.

Figure 1: Simple mockup of the finger to get a sense of how the technology interacts with hand in 3D space.

Figure 2: Mockup of finger constructed with the servo motors, tape and a piece of plastic.

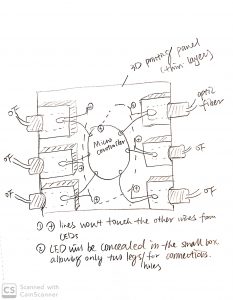

Figures 3 and 4 depict the current CAD (using Fusion 360) for the finger. Note that I am still thinking about the mounting to the hand. While it should be rigid it must also be comfortable (though the finger is worn over the glove so there is some cushioning already on the hand.

Figure 3: View of finger backside.

Figure 4: View of back of hand, note the finger mounting location that I am considering.

Materials List

Home Assistant Sub-Project

- Particle Photon – $19.00 (1)

- Flex sensor – 4.5 inches – $12.95 (1)

- Flex sensor – 2.5 inches – $7.95 (1)

*After initial prototype, purchase more flex sensors.

SRF Sub-Project

Already purchased / owned

- Glove for prototype [final version subject to change based on prototype]

- Sparkfun IMU – $14.95 (1)

- Flex Sensor – 4.5 inches – $15.95 (1)

- ESP32 Dev Board – $15.00 (1)

- High Torque Micro Servo – $9.95 (3)

- Resistive Force Sensor – $7.00 (1)

- Flex sensor – 4.5 inches – $12.95 (1)

Future / After initial prototype

- Resistive Force Sensor – $7.00 (5)

- Flex sensor – 4.5 inches – $12.95 (3) and/or Flex Sensor 2.5 inches – $7.95 (8)

Areas of Concern

For the glove we will continue to explore the mounting strategies for the flex sensor. Once we complete this we will need to capture gesture data. Currently there is no concern with this aspect however feedback and suggestions for mounting are welcome.

In regards to the SRF subproject, Curt still needs to figure out how to mount the finger. The original idea was to modify a skateboard / snowboard arm brace but a suggestion that was brought up was to modify a soft-support brace to allow full wrist movement. Again suggestions and feedback is welcome.