- Safe Sleeve

- Jacob Cordover

- Safe Sleeve is a soft, functional sleeve that conveys biomechanics that have been historically confined to clinical settings and cost prohibitive motion capture equipment.

- Video:

- Poster:

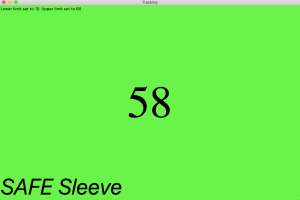

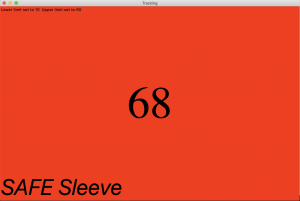

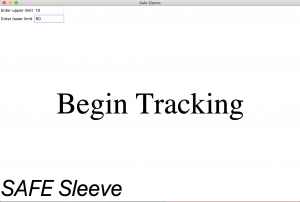

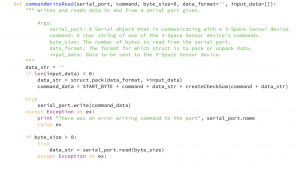

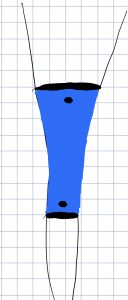

- Safe Sleeveis a soft knee sleeveintegrated with two inertial measurement units. Safe Sleevecalculates the angle of the knee joint— a task traditionally completed with a goniometer— by utilizing the two inertial measurement units which calculate each sensor’s angle relative to the gravity vector. These two values are subtracted from each other and streamed wirelessly to a computer via Bluetooth. The user can interact with the custom-built application in order to set bounds for flexion or extension. If the bounds are breached, the application will flash red, otherwise it will remain green. Additionally, the user can examine flexion and extension from entire streaming session with a line graph.

- Overall, I am very pleased with the outcome of this project. From the beginning, I wanted to work on a project catered towards sports and/or healthcare as this is what I am most interested in. With zero background in any design related fields, I tried to tailor my project towards what I was more comfortable with. I could have tried to construct the knee sleeve myself, however I don’t think I would have been as pleased with the final result as I am. Because I worked on this project solo, I invested time into getting the best data from the sensors as possible, along with creating a more seamless user experience, rather than focus on trying to achieve something I know I am not as strong in, which could have led to more frustrations and less to show for my efforts. Thus, I am left feeling pleased and optimistic about what I was able to achieve with my project, from ideation, to each milestone, to the final product, to the future of the sleeve.

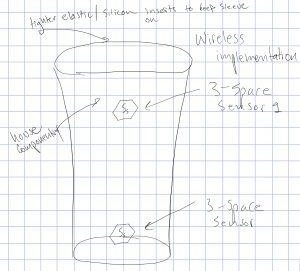

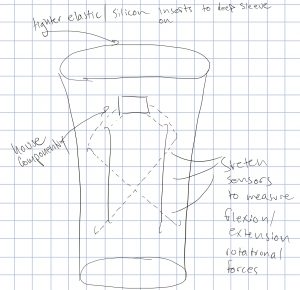

- The original intent of this project was to create a soft, functional knee sleeve that would convey flexion and extension data in situations where traditional means of collecting this data were too costly and/or impractical. When I started the ideation process, I had a few ideas of how to accomplish this goal: one, I could integrate either conductive fabric, stretch sensors, or flex sensors onto the sleeve and wire them to a Bluetooth microcontroller, or I could go the route I ended up using, implementing IMU’s with Bluetooth to achieve my goal. Ultimately, I decided that using IMU’s would be more conducive to achieving the overall goal of this project— to create a sleeve as functional as possible. Each additional piece of hardware introduced into the sleeve created another possible failure point and took away from the overall functionality of the sleeve. However, I still was looking for a solution to contain two batteries, two IMUs, a Bluetooth module, and a microcontroller in my sleeve in a way that would achieve the intent of my project. Thus, when I came across the Yost sensors that, it just about solved every issue in creating as functional of a sleeve as possible in an extraordinarily elegant way.

The sleeve has no wires, it did not need to be soldered, its footprint is significantly smaller than having to source each part individually, and the sensors are able to be anchored to the sleeve with virtually zero extra bulk on the outside of the sleeve.

While I did pay a premium for the sensors, I am very confident that this was the best solution in attaining my goal of creating a functional sleeve that conveys flexion and extension data. At each step of the process, every decision was made with this goal in mind, and as a result, I believe I have surpassed my goal of creating this functional sleeve that conveys flexion and extension in ways that turned out even better than I had envisioned.

As for the actual data, I have gotten the sleeve to the point where it looks to be outputting acceptable data. From eyeballing angles, it looks to return an angle around 3-5 degrees from which one would expect, however, I would like to see the sleeve compared and potentially calibrated against a goniometer.

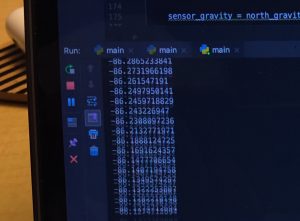

- There were two main challenges that I faced in creating the final product, the first of which was what methodology I should employ to get my intended data. A large issue in calculating flexion angles with both goniometers and wirelessly is that the human body is one, soft, and two, not flat. Thus, when using a goniometer, there are specific bodily landmarks to determine placement for an accurate measurement. Likewise, when using IMU’s, the sensors will never be flat, and additionally, it is not practical to ensure precise placement every time the sleeve is worn. As a result, I had three possible implementation plans: quaternions, Euler angles, and taking angles with respect to gravity.

Quaternions are an extension of the complex number system, and while they are the most complex approach to solving the problem, they offer an extremely robust solution, while avoiding known problems of Euler angles, like gimbal lock. Essentially, quaternions would create rotational offsets that could be accounted for when calculating the final angle of interest, no matter the orientation. Theoretically, this works well, however after I implemented this approach, the data would just not cooperate. I could get somewhat accurate results for around twenty seconds or so, however the angle would start to drift until the angle became completely nonsensical.

Taking angles with respect to gravity and subtracting them was the simplest approach, however it seemed to give the best angle. While this solution may not be as robust as quaternions, it was not plagued by the issues the quaternion approach presented. This method was so satisfactory, that I decided that any improvement Euler angles could potentially provide was not worth it, rather I spent the rest of my time working with the second major problem, Bluetooth connectivity.

Getting the sensors to talk to my computer hard wired was not much of a problem at all, however unplugging the sensors and communicating via Bluetooth proved to be the biggest challenge of this project. For some reason, the sensors would work fine for a few seconds and then there would be an unresolvable communication error resulting in a crash. I tried both windows machines and macs to no avail. I tried all sorts of error handling in the backend to no avail. I also made sure low battery wasn’t affecting the Bluetooth communications. Nonetheless, I noticed a few things, the first of which is that the sleeve works better when I’m around fewer devices. At the showcase, Bluetooth didn’t work for longer than a second or two. During class time, the sensors sometimes work for 10-15 seconds before crashing, however at home, the sensors will work for minutes at a time, which makes me think that the sensors are susceptible to some kind of interference.

The other thing I noticed is that the longer the sensor has been on and connected and reconnected to Bluetooth, it works longer before crashing. I am still not sure as to why this is the case.

Unfortunately, I didn’t solve the Bluetooth issue. As mentioned, error handling in the backend cast the sensors into an infinite loop of reading back nonsensical values. Thus, to work around the issue of communication error, there is a button in the user application that terminates and reconnects the streaming session. The process only takes a second or two, so until the Bluetooth issue is solved, this will have to suffice.

- Given more time, besides working more on the Bluetooth issue, I would harness more functionality from the IMUs. There are many different measurements that can be taken from these sensors with the accelerometer, gyroscope, and compass. While perhaps the scope of this project focused on the rehab aspect on trying to emulate a goniometer, given more time I would like to implement more performance-based features. For example, measuring a vertical leap, or measuring force produced by the leg. Performance asymmetries between the legs is a flag for increased injury risk, so this could also help further Safe Sleeveas an injury prevention tool.

Otherwise, the technology in safe sleeve can easily be ported into an arm sleeve. I’d have to do some more research into what mechanics are used in upper extremity recovery protocols as well as what performance metrics are used, but I believe the difficult part has been done.

- Materials:

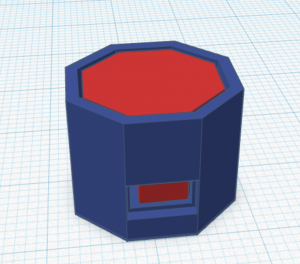

2 Yost Labs mini Bluetooth IMUs

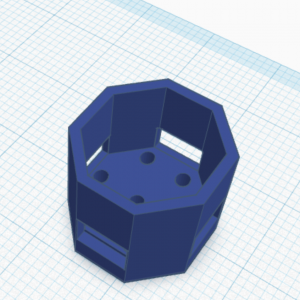

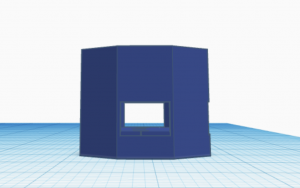

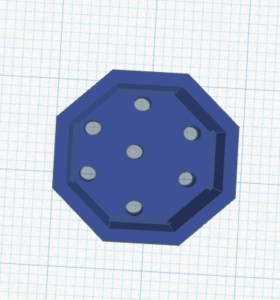

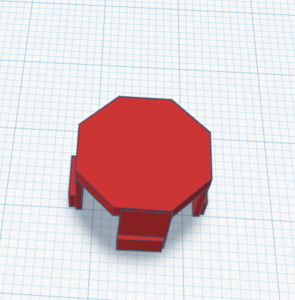

2 back plates with 4 anchoring screws

1 knee sleeve