Virtual Vermin

Jeff Brandt

One Sentence: The Virtual Vermin is a glove that functions as a computer mouse designed to relieve muscle exhaustion and reduce the possibility of carpal tunnel.

Video:

Image of Final Poster:

What does the project do?

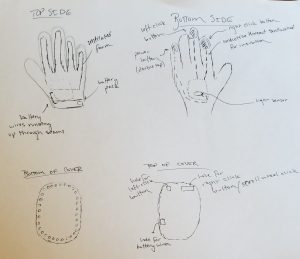

The Virtual Vermin places the buttons of a computer mouse into the user’s fingertips. It works by using a circuit board that has connections to soft buttons which are placed inside the fingertips of the glove. To use the Vermin, the user simply has to place their hand inside the glove and push down with the finger corresponding to the desired button. In this iteration, the pointer finger acts as the left click, the middle finger acts as the click of the scroll wheel, and the pinky finger acts as the right click.

Overall feelings on the project

All in all, I am extremely happy with the way that my project turned out! I wish I could have spent more time making it look “prettier”, but I am still pleased with the fact that it actually works. I also wish I could have experimented with more materials to insulate the wiring as the comfort level could be improved. In the end though, I am proud of my work and think that it may have not exceeded the goals I had set but definitely met those expectations.

How well did it meet the original goals?

While I would still deem the Vermin a success, I think it didn’t quite meet the original goals I had at the beginning of the semester. Part of this is because I had painted a picture in my head of a glove with a logo and other bells and whistles to increase the aesthetic appeal. I really didn’t know just how much I didn’t know about computer mice and that caused me to delay the process of making it look good and focus more on the functionality. The other reason I think it may not have met the original goals is more of a technicality but this current iteration does not allow the user the ability to scroll down a web page like they would with a traditional mouse. However, I think this potential downfall was worked around because the user still has the ability to click the scroll wheel and this is actually more important than scrolling when using SolidWorks (which was the original design intent for the mouse).

Largest hurdles that I needed to overcome

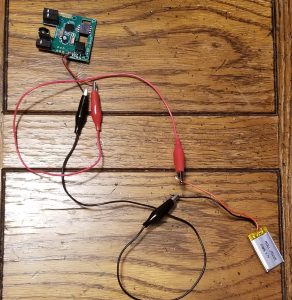

The largest hurdle that I needed to overcome was my lack of knowledge in regards to how a computer mouse worked. I didn’t know just how complicated the circuitry and LED light reader of an optical mouse were. I had original plans of just using an accelerometer however, I quickly found out that the location sensitivity was much more important that I previously thought. Another hurdle that I needed to overcome was my subpar soldering skills. While I did improve them during this semester, I needed much better soldering to prevent all of the conductive thread connections from breaking apart.

Future plans if I had more time

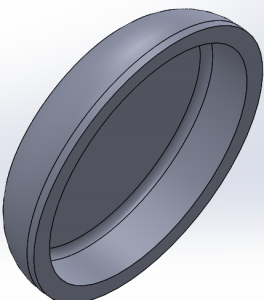

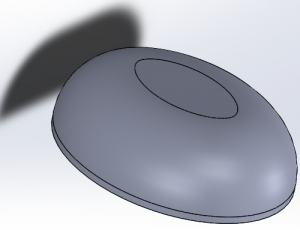

If I had more time, the first thing that I would do would be to sew my own glove. With the insulation that was required to protect the conductive thread and the cover for the circuit board, the glove felt a lot tighter than it did when I originally wore it. I think this would help the hard base plate of the mouse to feel less bulky as well as provide more comfort for the wearer in the palm region where the cover extrudes. Additionally, I would try to find another solution for the circuit board cover because it was much thicker than I originally intended. The first two 3D prints failed because the curvature of the cover was too complex to make with my desired thickness.

Materials List:

Wireless Mouse // Quantity: 2 // $9.99 // https://www.amazon.com/gp/product/B015X2OD52/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

Conductive Fabric // Quantity: 1 sq. ft. // ? // Supplies in classroom

Conductive Thread // Quantity: 1 yard // ? // Supplies in classroom

Gloves // Quantity: 1 // $11.95 // https://www.amazon.com/Agloves-screen-gloves-texting-gloves/dp/B004A9FI2M/ref=sr_1_6?keywords=thin+glove&qid=1552266834&s=electronics&sr=1-6

3D printed cover for circuit board // Quantity: 1 // $2.14 // created in Solidworks