InGlove

Curt, Vedant, Shruthi

Project Sentence

Home Automation

SRF

Human augmentation device providing users with an extra thumb for everyday tasks.

Weekly Accomplishments

Curt –

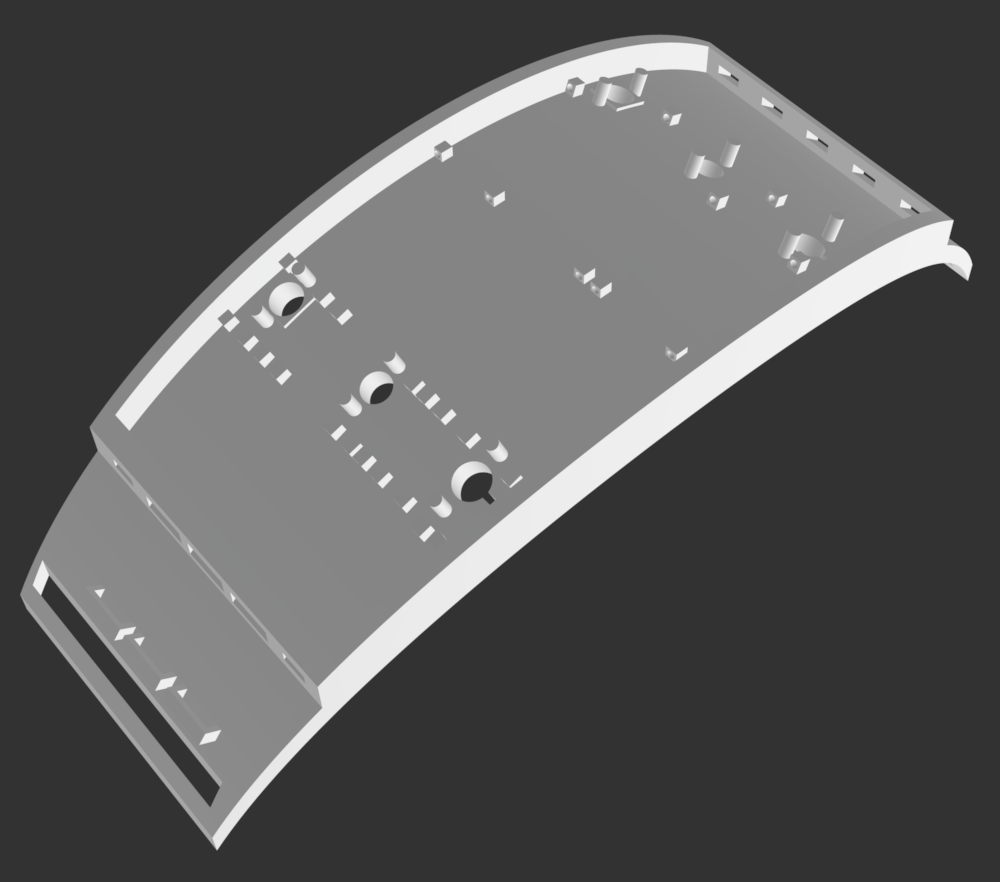

This past week I worked primarily on constructing a stable brace for the SRF finger. The brace now has a leather support which reduces the elastic effect of the neoprene. Additionally, sewed several tucks into the brace neoprene in order to have it better conform to the hand.

I have received the glove liner from Amazon (though later than expected). This next Monday I will be focusing all of my effort on constructing / applying all of the flex sensors.

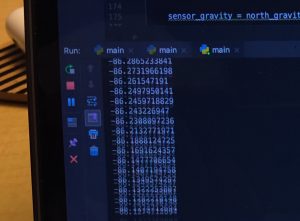

Using fake data, I created several ML python scripts in preparation for the flex sensors. Current plan is to have the ESP32 connect to laptop via Bluetooth in order to run the ML solution for the showcase. Unless the model is computationally cheap enough to run on the ESP32 (either main core or secondary).

Working with the servos currently, I have noticed the torque could be improved. This is something that I somewhat anticipated. Not going to address it in this iteration of the project, though the solution is to add a custom gearbox (perhaps worm gear?) to the output of the servo.

As for my power system, I have a USB battery pack that I tested with the servos. It seems to handle the current draw with all three. It has two USB ports so it is possible to power both the controller and the servos using it, however I may purchase a secondary supply for the controller in order to isolate the voltage sag from servos.

For the poster I have started to lay out the information and determine which pictures I want to include. I need to find someone to assist me either as a hand model or to take the pictures.

Finally, I have found a name for my project that captures the essence of this step in embracing my transhuman philosophy. While I will still use the term SRF to describe it, the device shall be labeled: Táltos-oid. Táltos comes from Hungarian mythology and is a shaman that has innate supernatural power and can be identified by several possible abnormalities. The one I am drawing upon is that a Táltos can be identified by an extra finger. What I like about this name is that this device, poetically, allows me to take a step toward transcending my humanity.

Vedant –

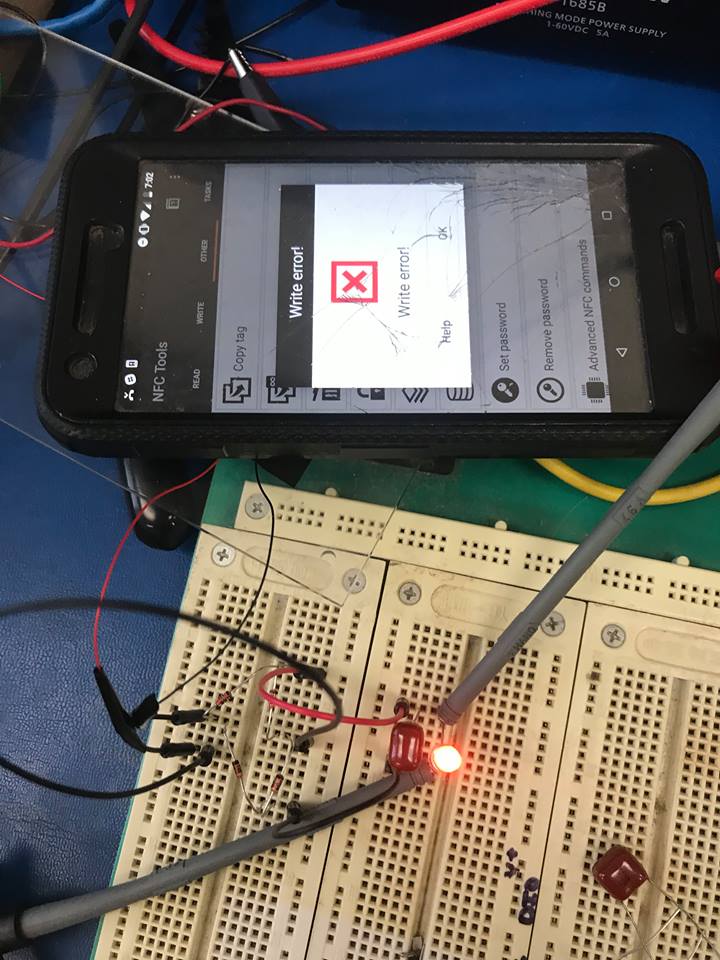

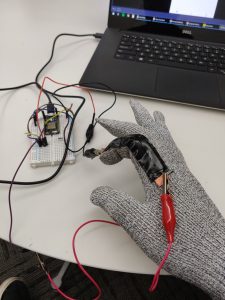

This week I worked on looking up how to implement an IR transmitter using the Patricle Photon. I was able to make the circuit for doing so, but had some trouble with the code, as there was multiple errors in the IR codes.

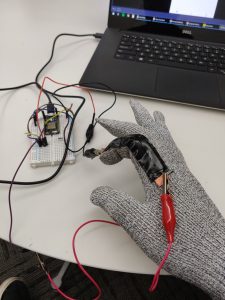

Additionally, we sewed on one of the DIY flex sensors onto a glove for the in-class demonstration and were able to successfully turn on a smart light with the flex of a finger (with a 20 second delay). However, we had to look into a DIY sensor that used fabric instead of electrical tape, to integrate it into the glove well, and we were able to get it to work successfully.

DIY Flex Sensor integrated into glove:

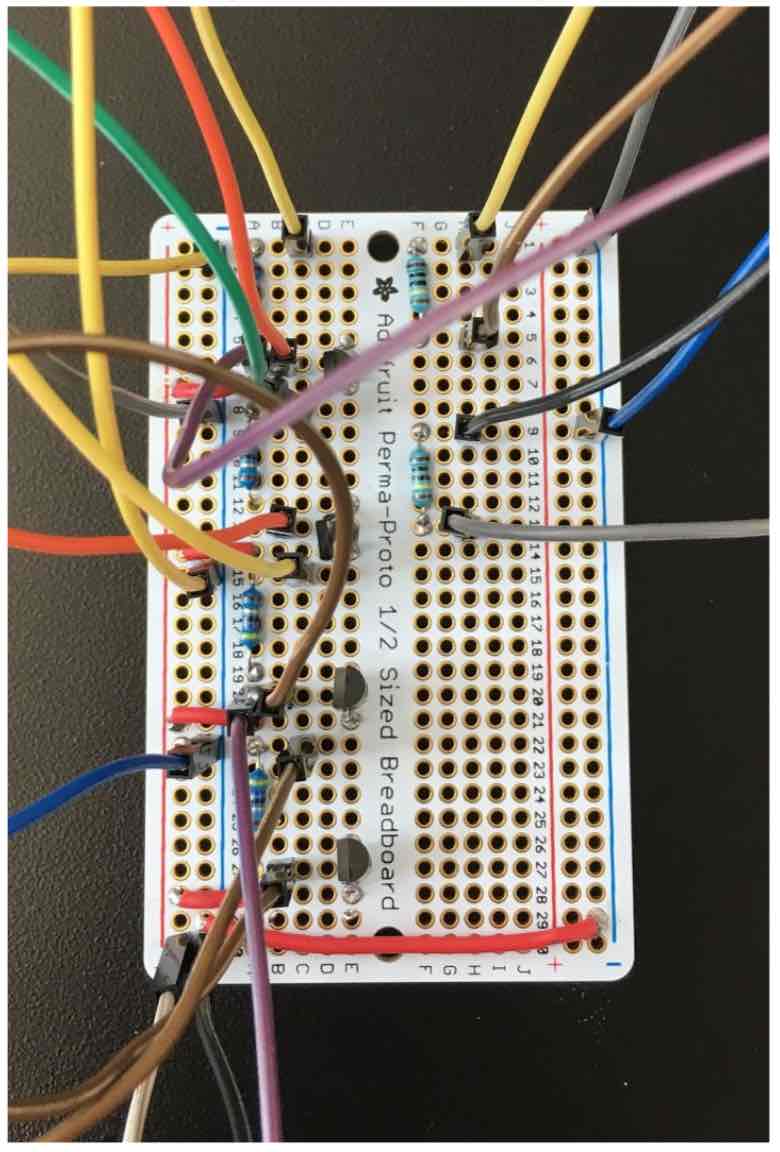

IR Circuit :

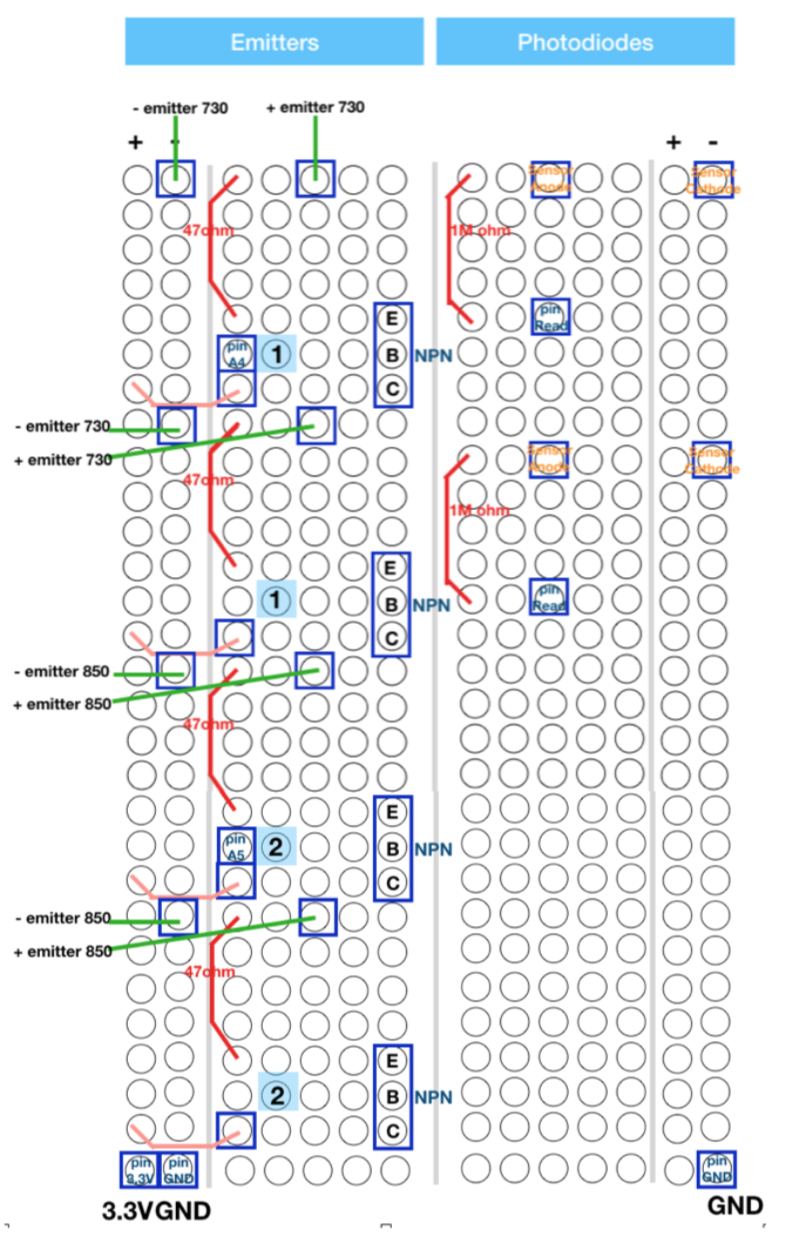

DIY Fabric Flex Sensor

Shruthi –

This week I worked mainly on the physical aspect of the glove and assembling the bits together. We initially sewed on a flex sensor we had made out of velostat and tape. However when we sewed it on, it did not integrate well with the fabric of the glove. The sensor also often dislocated reducing the consistency of our output. After talking to the professor, we created a similar sensor using fabric as the insulator instead of tape. Although the readings were changing in much smaller granularity, it sewed on really well and a much better aesthetic choice.

I also tried making the android app, however the rest api error continued and the app did not work. We might fallback on IFTTT to the extent possible.

Material List

Home Assistant Sub-Project

- Particle Photon – $19.00 (1)

- Flex sensor – 4.5 inches – $12.95 (1)

- Flex sensor – 2.5 inches – $7.95 (1)

*We decided to go ahead with more of the DIY flex sensors. So we might possibly need more velostat and copper sheets and conducting thread.

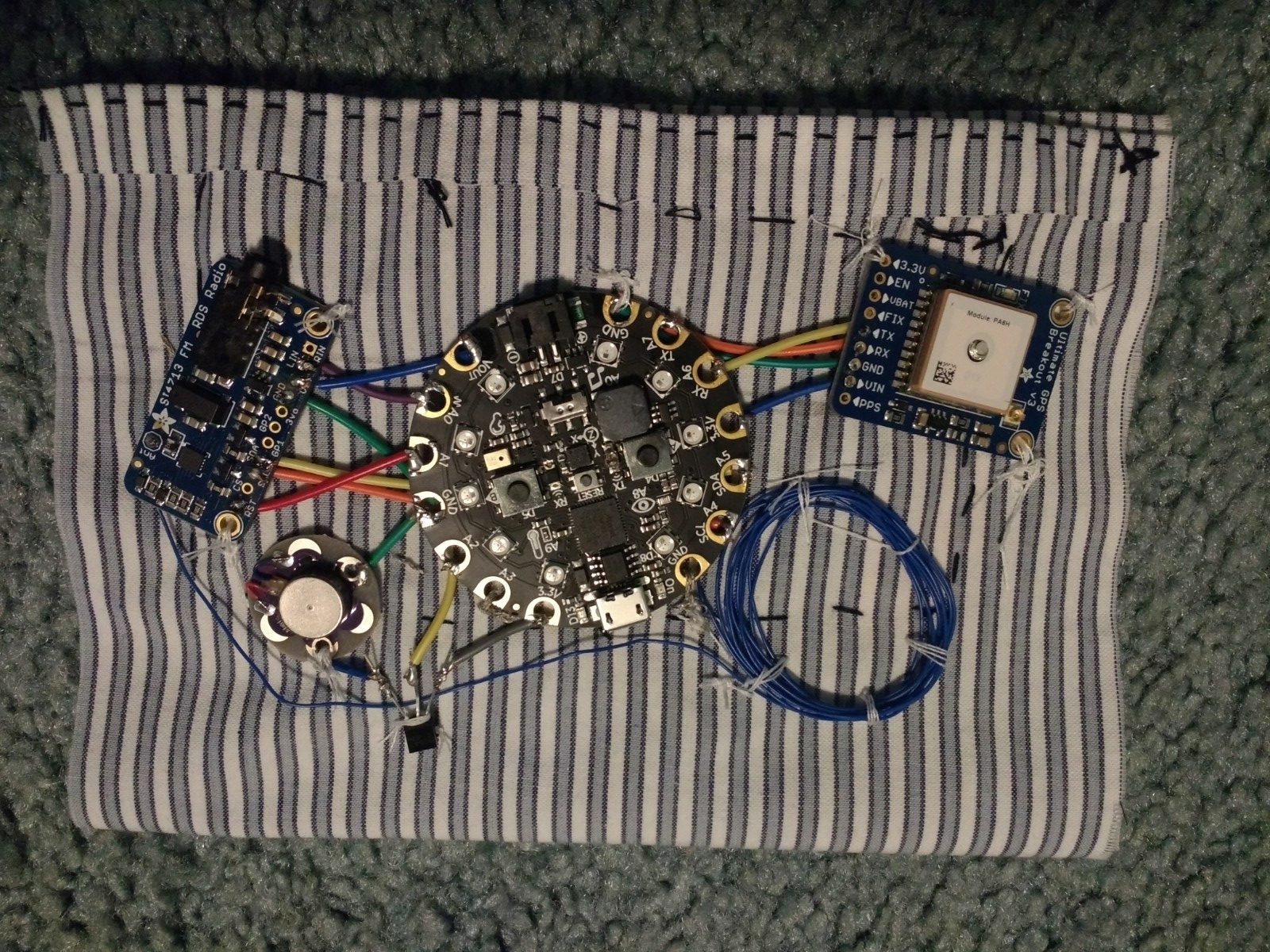

SRF Sub-Project

Already purchased / owned

- Glove for prototype [final version subject to change based on prototype]

- Sparkfun IMU – $14.95 (1)

- Flex Sensor – 4.5 inches – $15.95 (1)

- ESP32 Dev Board – $15.00 (1)

- High Torque Micro Servo – $9.95 (3)

- Resistive Force Sensor – $7.00 (1)

- Flex sensor – 4.5 inches – $12.95 (1)

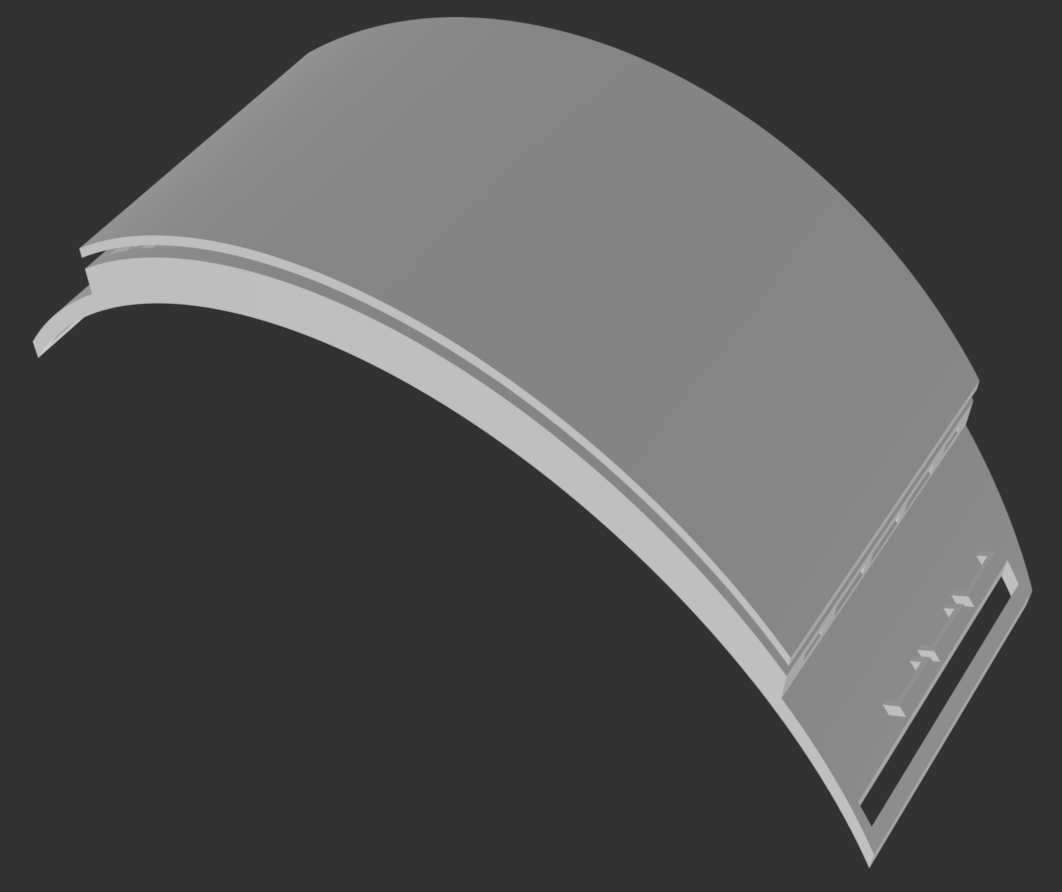

- 3D printed SRF – ~$9.00 (N/A)

- Glove [Final design] – $14.99 (1 ordered)

- PCBs – N/A (N/A ordered)

Need to Purchase / Being Shipped

- Resistive Force Sensor – $7.00 (5)

- Flex sensor – 4.5 inches – $12.95 (3) and/or Flex Sensor 2.5 inches – $7.95 (8)

- [Expected 4-18-19] High Torque Micro Servo – $9.95 (1)

- [Expected 4-18-19] 3.3V to 5.0V Level Shifter IC – ~$1.00 ( 1)

- [Expected 4-18-19] I2C Servo Driver Board [in case issue with microcontroller persists] – $14.95 (1)

- [Submitted request 4-13-19] Updated 3D printed SRF components $5.00 (N/A)

Areas of Concern

Curt –

Main concern is getting the flex sensors and algorithm done on time. I will be focusing exclusively on the flex sensors Monday and Wednesday so that I can make final adjustments the week after. Secondary concern (though very much related) is time. I have parts in shipment from Adafruit due Thursday to fix the lack of the rotational joint in the finger. Also I need to receive the 3D printed parts for this upgrade.

Vedant –

My main area of concern as of right now is to successfully get the particle to send the IR signal I want it to send. I am still trying to work on fixing the bugs in the code for the particle, but any help on that end would be great.

Shruthi –