Virtual Vermin

Jeff Brandt

One Sentence: A flexible, full functioning computer mouse designed with 3D modeling in mind.

(I think this is dressed up a bit more than “a computer mouse in a glove”)

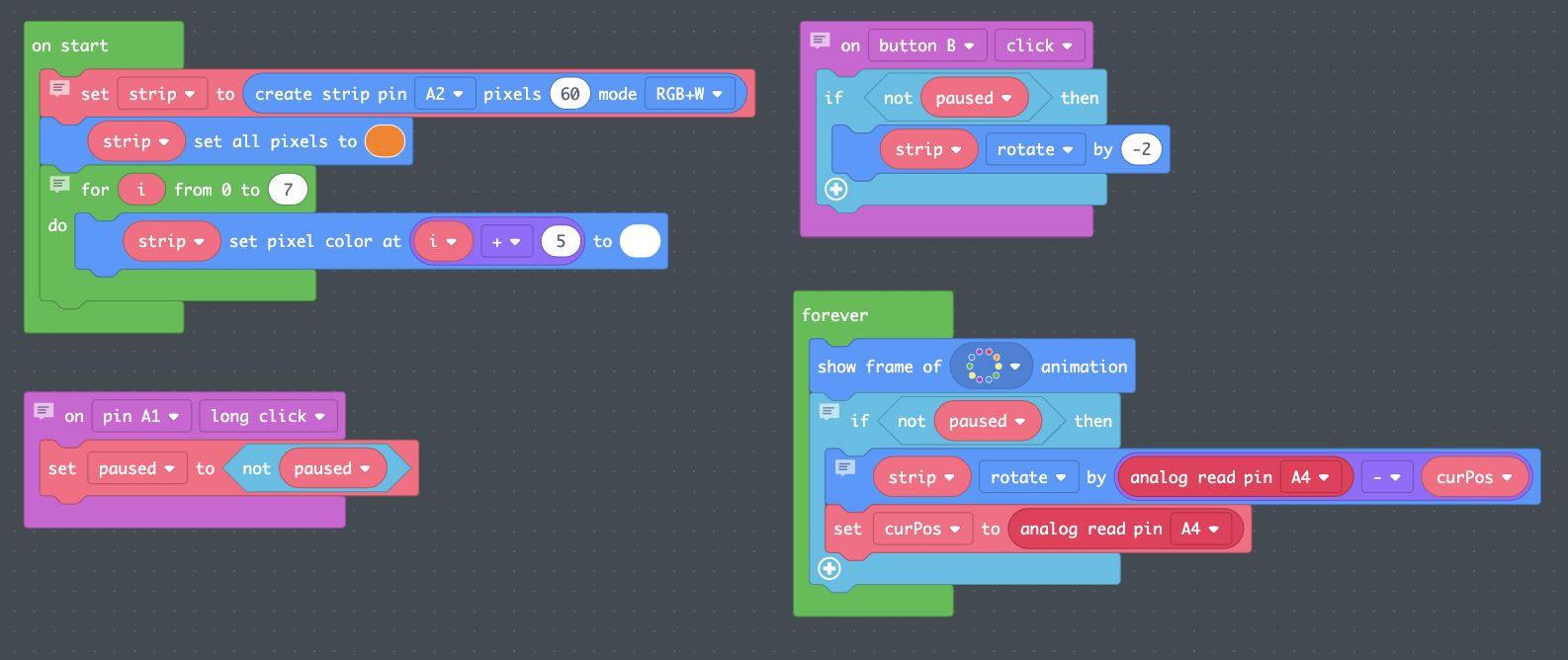

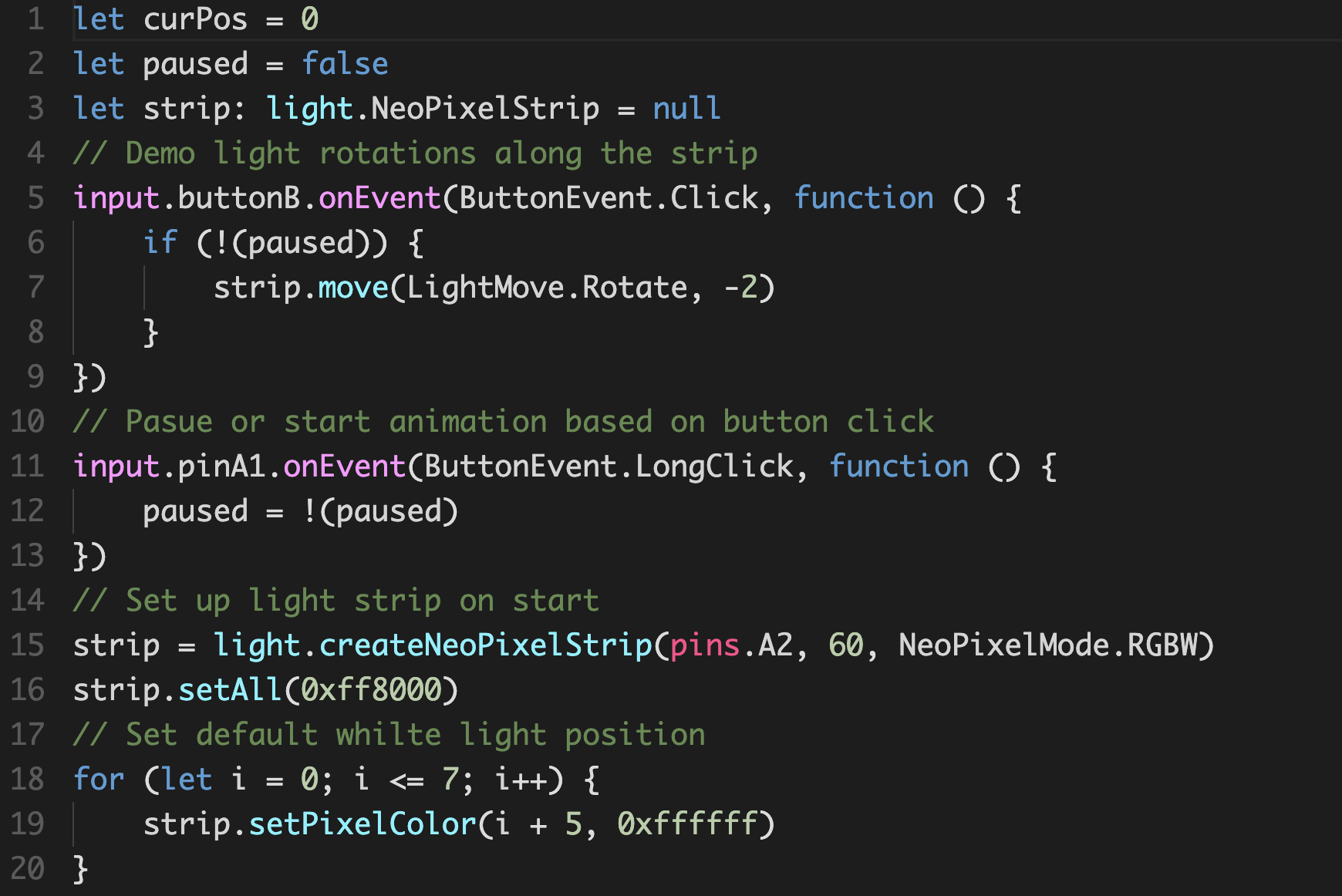

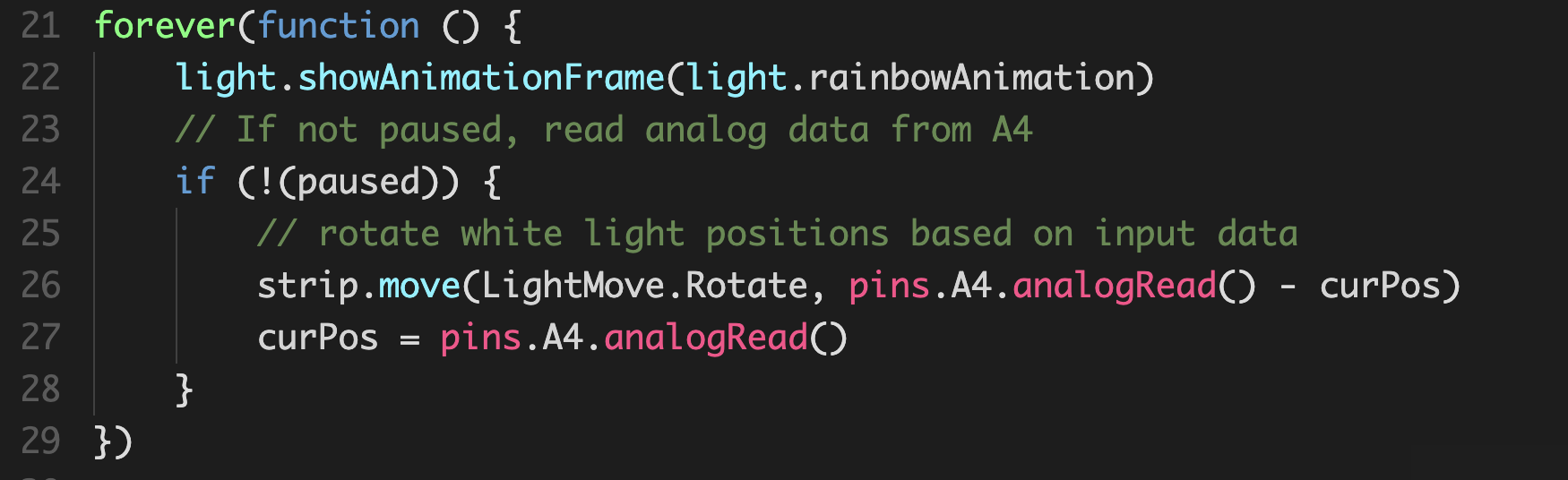

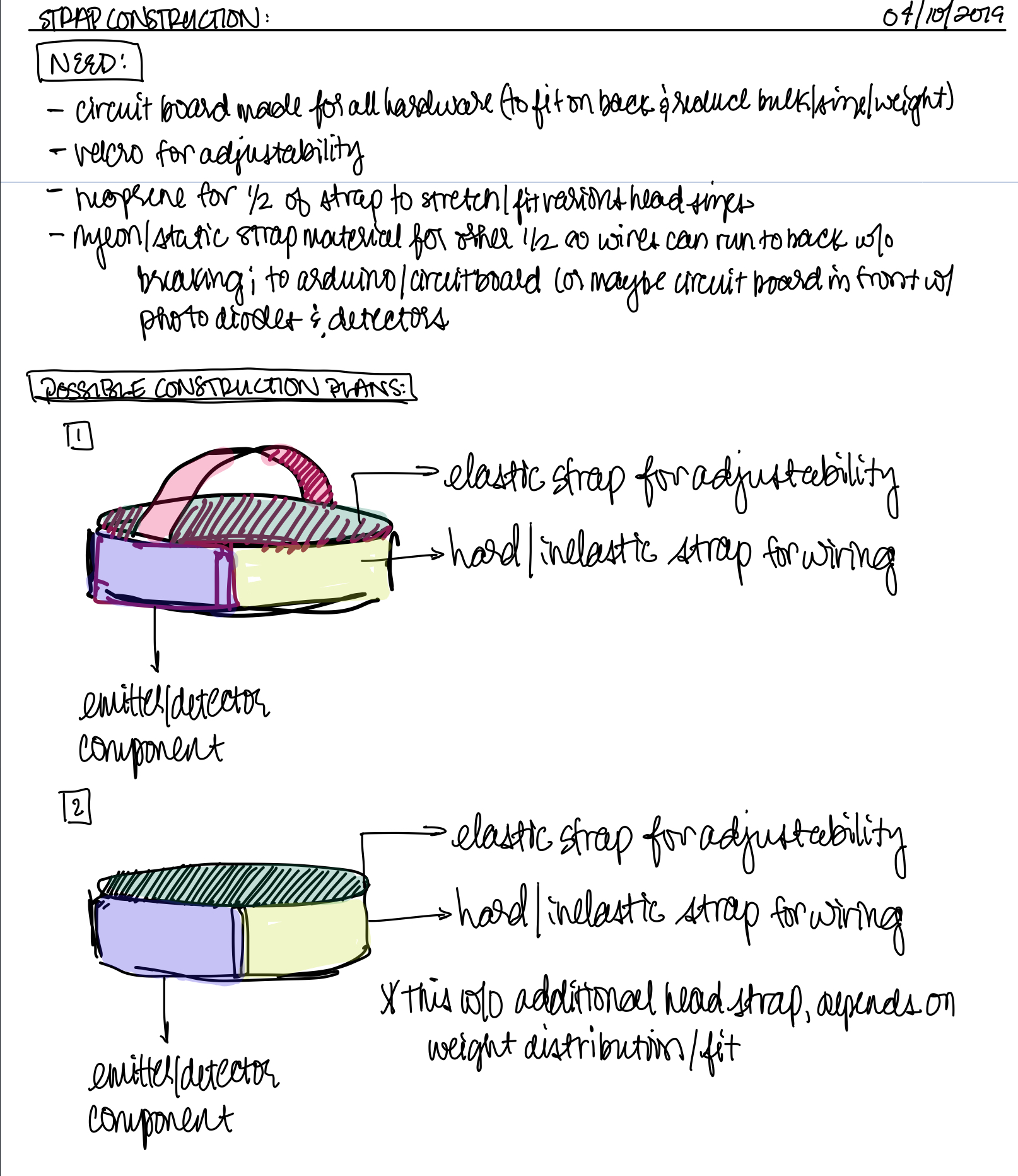

Weekly Accomplishments:

- Reconfigured soft switch buttons to stretch the conductive fabric further down the fingers

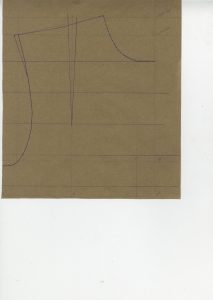

- Submitted 3D print to Makerspace to print circuit board cover

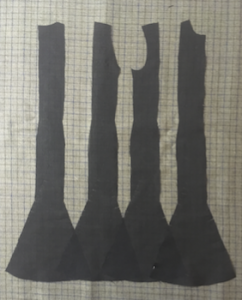

- Deconstructed glove so that the soft switches can be integrated

Images:

Material List:

Wireless Mouse // Quantity: 1 // $9.99 // https://www.amazon.com/gp/product/B015X2OD52/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

Conductive Fabric // Quantity: 1 sq. ft. // ? // Supplies in classroom

Conductive Thread // Quantity: 2 yds. // ? // Supplies in classroom

Negative Poisson Ratio Foam // Quantity: 1 sq. ft. // Free // Supplied by my research lab

Gloves // Quantity: 1 // $11.95 // https://www.amazon.com/Agloves-screen-gloves-texting-gloves/dp/B004A9FI2M/ref=sr_1_6?keywords=thin+glove&qid=1552266834&s=electronics&sr=1-6

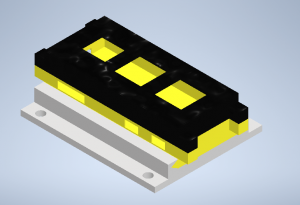

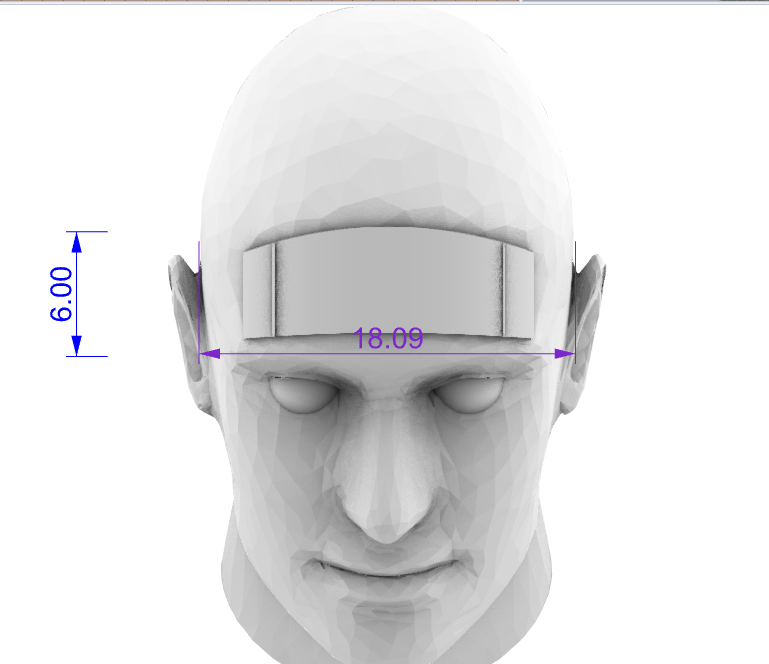

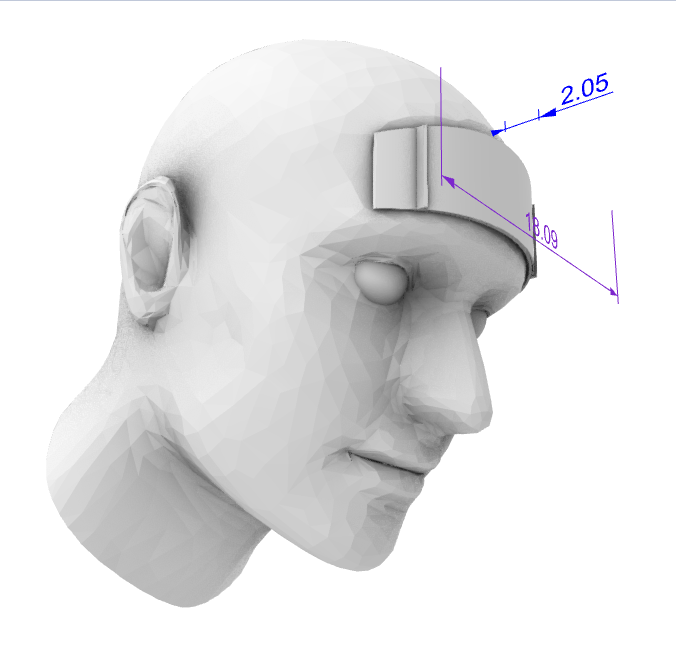

3D printed cover for circuit board // Quantity: 1 // $2.14 // creating in Solidworks

Areas of Concern:

Right now, my biggest area of concern is trying to determine how to best insulate the conductive fabric/thread paths that extend from the finger tips to the palm. I have a vision of how to do it in my head but as I have never had to sew multiple layers of things before, I am not sure if there are any tips that could be of help. Marianne, if you are available to run through this process again with me for a short period of time on Monday that would be great.

As for the electronics component, Kevin, I think I decided against the integration of a microcontroller. My current plan may not be the ideal configuration for an actual go-to-market product however it will accomplish, if not exceed, the goals I had set at the beginning of the semester for a first iteration.