PROJECT POST #4

Project Title: Vis Hat

Project Team: Lydia, Fu, Jay

Weekly Accomplishments:

Lydia:

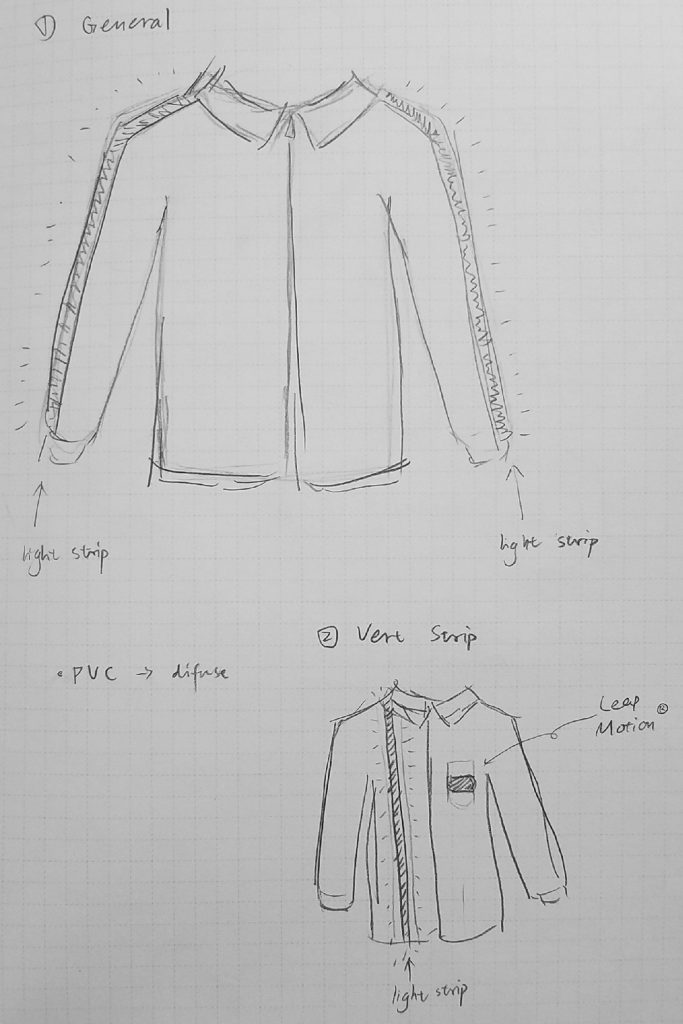

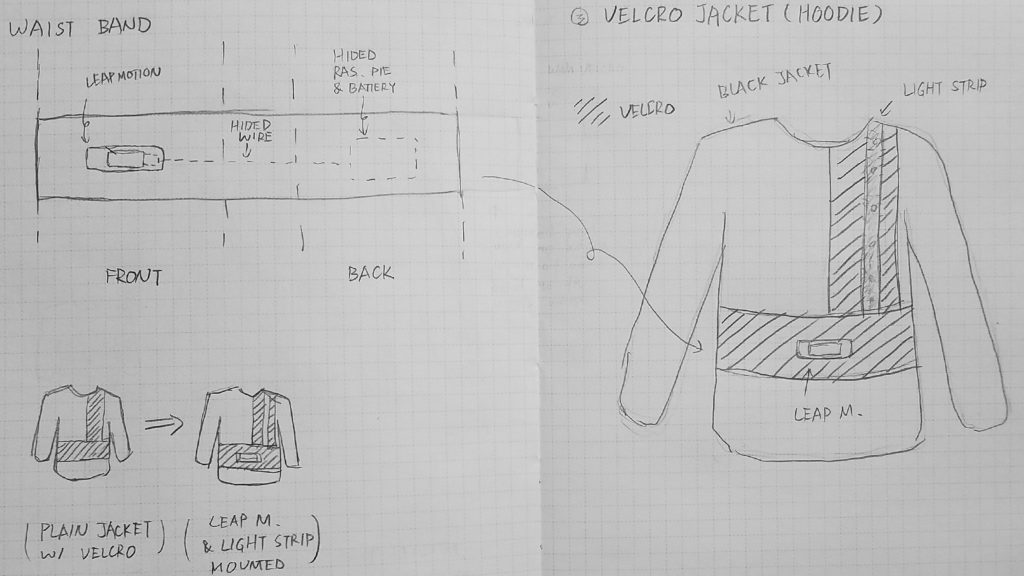

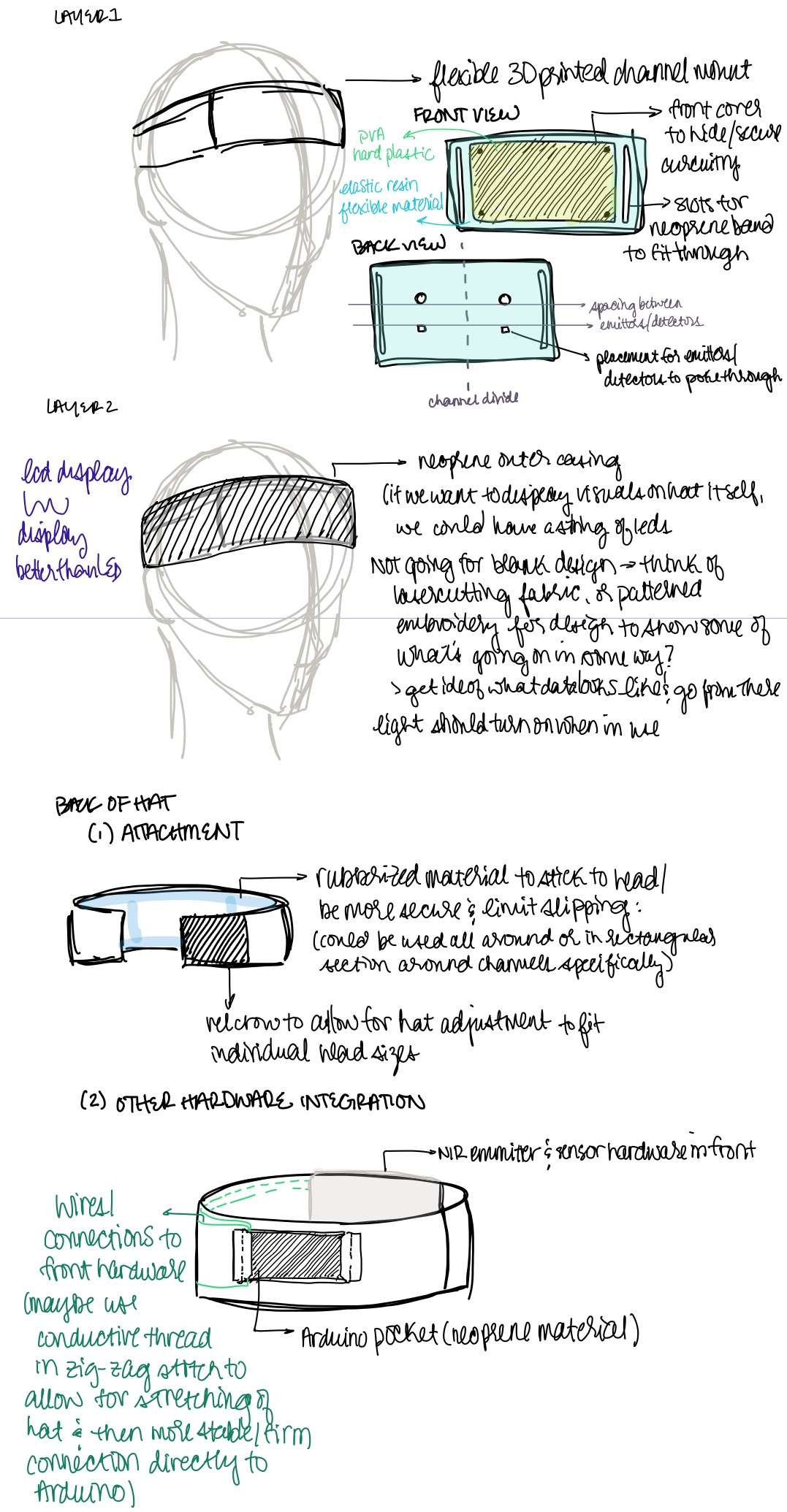

- Researched: visualization software and data transferring methods; existing data visualization; 3D printing materials

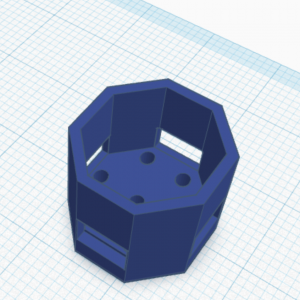

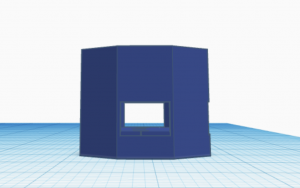

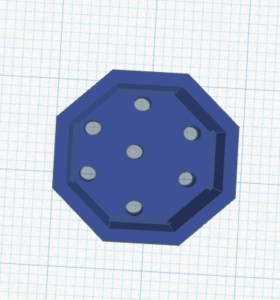

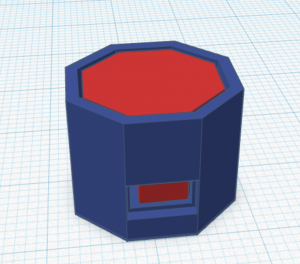

- Visited maker-space and discussed 3D printing material specifications and properties to find best suited material for our project (we will be using elastic resin 3D printing material for the base and hard pva for the cover

- Further drafted construction of 3D printed components and design of VisHat overall

- Continued compiling experiment/testing procedures for data collection in response to different stimulus

Fu:

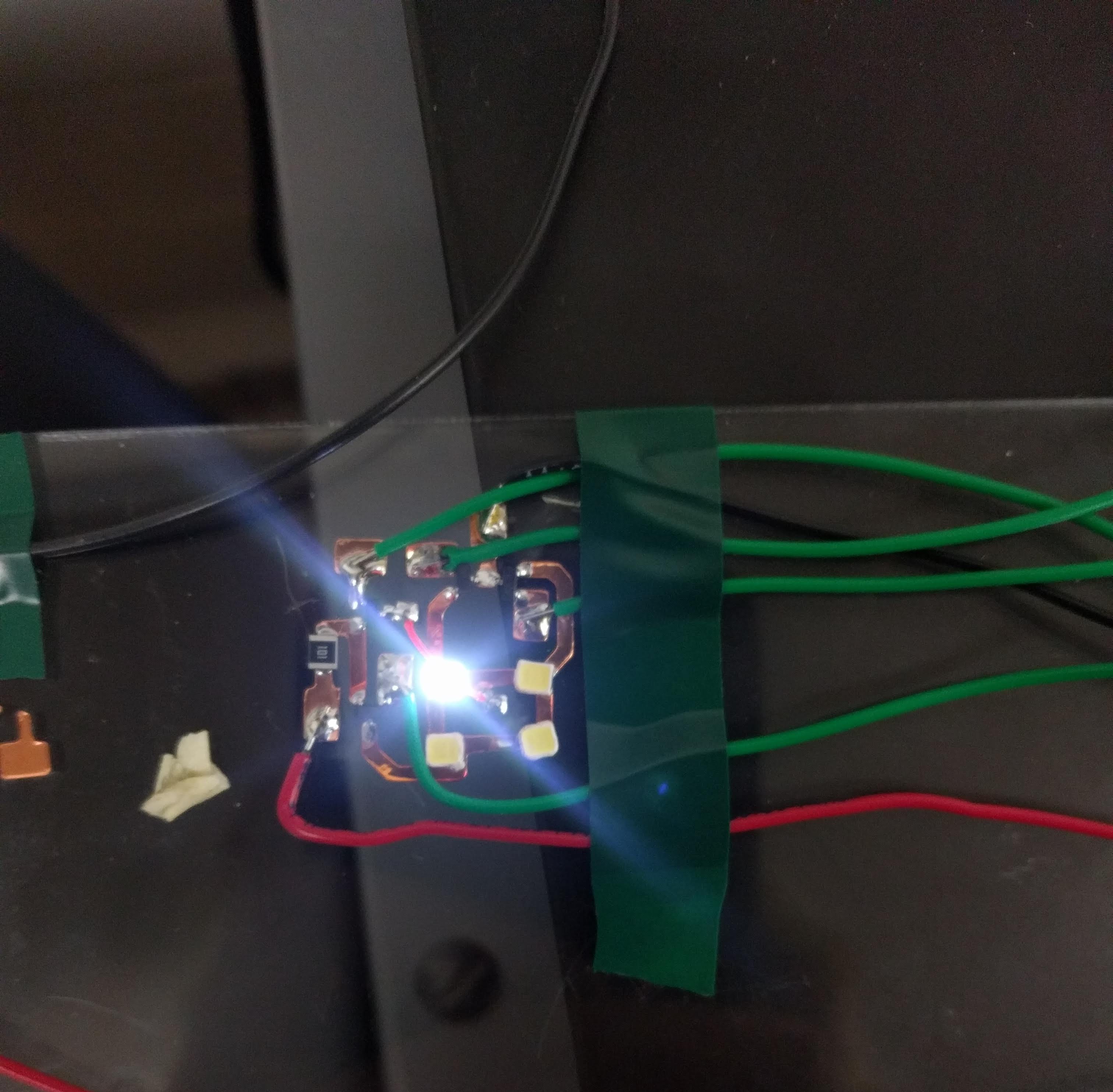

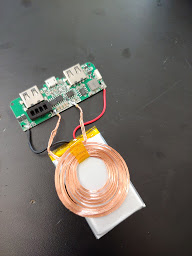

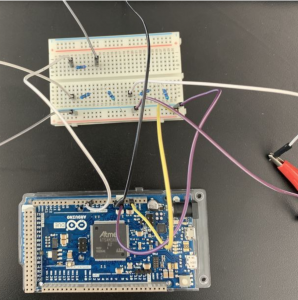

- Finishing emitter and photodiode circuit connected to Arduino Due.

- Test and complete Arduino Due analog read and pin out control.

Jay:

- Completed emitter detector circuit and tested on head

- Diagramed finished circuit

- Fine tuning relating to current going to emitters, and sensitivity of the photodiode

Images:

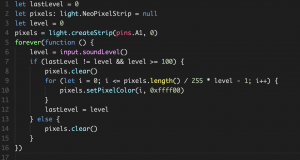

Image 1 is a photo of the circuit setup connected to the Arduino Due

Image 2 is a diagram of the VisHat headpiece construction

Material List:

| title/link | # needed | price/unit | notes | shipping and tax | TOTAL PRICE: |

| arduino due | 1 | 34.43 | 34.43 | ||

| NPN transistor | 1 | 5.99 | this one unit contains ~200 resistors | 5.99 | |

| 730nm emitter | 2 | 8.61 | 9.54 | 26.76 | |

| 850nm emitter | 2 | 1.46 | 2.92 | ||

| 850 max nir detector/sensor | 2 | 5.37 | 9.02 | 19.76 | |

| bluetooth | 1 | 28.95 | RN41XVC (with chip antenna) | 8.81 | 37.76 |

| 850nm emitter | 2 | 1.46 | To account for trial and error hardware testing | 7.99 | 9.45 |

Project Concerns:

Now that we’re getting to the point of proof of concept a concern we may face might be noise within the data. We’ve been able to get response from the detectors that seems consistent with actions but whether or not the data collected when the emitters and detectors are placed on the head is from actual refraction or just from external stimulus may be hard to detect. Hopefully when we get to the testing stage we’ll know more about the state of the data.

Additionally, the 3D printing material we’ll be using is clear/transparent and that, too, may affect the kind of data gathered. The material can be painted so this could be a good plan to reduce additional noise.

Finally, we’re coming up on the mounting stage where the soon-to-be 3D components are attached/positioned on a user’s head. Everyone’s head shape is slightly different, so finding a way to make these as universally-fitting as possible while still maintaining structural integrity to the degree we need for the channels to remain stable enough may be difficult. The plan for now is to print a version 1 of the model, test it and its fit, and see if additional material integration like firm foam or memory foam to fit the hardware more securely to someone’s head might be needed for this to work best.