Temporary Circuitry Tattoo

John Compas

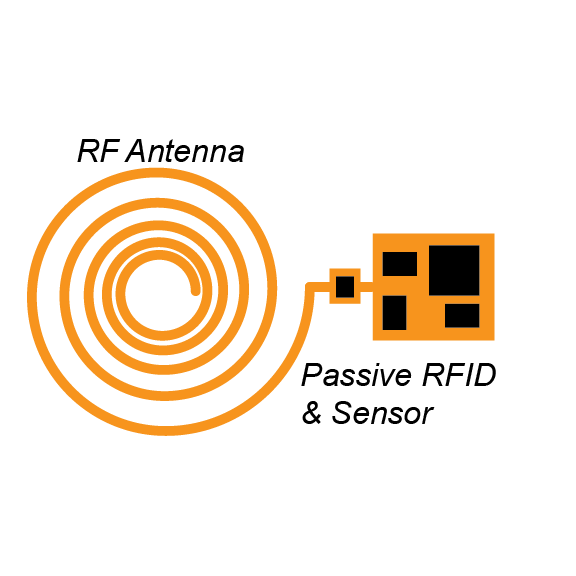

I would like to explore the possibilities of using gold leaf, tattoo paper, and SMT components to create wearable circuits. These temporary tattoos could be artistic, lighting up in response to the wearer’s environment, or more utilitarian, such as utilizing near RFID to respond to a request with sensor data and an ID. I’m interested in investigating the space of what is possible with this topology especially with antennas and RFID technology.

My project is for anyone, to show to demonstrate the capabilities of the technology and fascinate people.

Interfacing with a complete device would be simple. The tattoo would be applied like any other with a spray bottle of water to get the adhesive to activate on the wearer’s skin. In the case a passive UHF RFID tag, the sensor would lay dormant until activated by a strong RF emitter. Storing the received RF energy in a capacitor, the integrated sensor IC would read a sensor value and respond to the request as dictated by UHF protocol ISO 18000-6C. The reader would then report this value to a tablet or phone.

More artistic designs could change LED color and intensity based on skin temperature and conductivity, or by the intensity of received RF signals in a certain band. For example, LEDs could visualize the intensity of different frequency signals around the wearer using multiple antennas with varying resonant frequencies.

Existing work as focused more on either ease of use, or improving some technical aspect of this technology. I would like to focus on antennas and poetic interaction with the user.

Project Inspiration

Duo-Skin, MIT

A project from a group of MIT, Duo-Skin aimed to demonstrate the ease of creating wearable, temporary tattoos. They were successful in creating computer-powered MIDI controllers, RFID tags, and letting a team of volunteers quickly create their own circuitry.

iSkin, Carnegie Mellon

iSkin was a much more engineered approach and came before the MIT study. They demonstrated interfaces using layers of cPDMS (a silicone elastomer) and touch. The study is good source of detailed information about how their capacitive touch sensors work but was less “friendly” than the Duo-Skin.

Project Sketch

Example UHF RFID Sensor, passively powered that responds with ID and data.

(I’m not great at antenna design, the feedpoint should probably be in the middle, but this is the idea)

Materials & Tools

- Gold leaf

- Tattoo paper

- SMT capacitors, transistors, LEDs, and ICs

- Altium Designer

- Small lithium-ion coin cell batteries

- Impedance analyzer

- Oscilloscope

- DC power supply

- Solder paste or solder

- Solder gun, heat gun, and reflow oven

- Laser cutter (potential)

- Electric stencil cutter

Skills & Concepts

I will need to research antenna design thoroughly, as I have little experience with it in the past. I’m aware of the challenges with circuitry and antennas in the gigahertz range but have never designed any myself.

Cutting the stencils will (hopefully) not be done by hand, but the layering of the tattoos will need to be done by me. Soldering the SMT components to the gold leaf will also potentially be a challenge. Burning the leaf out might be easy, but it seems like a challenge that has been overcome in the past so I’m hopeful that I will find a method.

Timeline

March 8: Order Prototype Materials, Find Tools & Initial Design

- Generate a more detailed list of materials needed for an initial prototype and find suppliers online

- Order materials and components

- Layout initial circuit designs in EasyEDA, layout footprints in Altium and generate stencil cut-outs

March 13: Demo of Circuitry

- Utilize gold leaf on cardboard or another surface to create initial powered circuitry

- Attempt to transfer to body, and develop a procedure for insulating layers

March 25: Duplication

- Successfully duplicate previous work, with battery-powered sensors, capacitive touch buttons, and LEDs

- Attempt to create RFID responsive tags with a simple IC and antenna

- Analyze antenna properties, characteristic impedance, and model gold leaf in antenna design software such as EMWORKS

April 8: Improvement

- Start work on passively powered RFID tags & sensor

- Iterate on the circuit construction process

- If work is progressing well, attempt a powered Bluetooth LE circuit

April 22: Environmental Testing

- Demonstrate design in the real world, and test durability and usability

- Make small changes based on the user experience of wearers

- Prepare multiple samples and demonstration “tattoos” for the show in April.

Fallback

As a whole, I see the antenna aspects of this project as the most challenging. I have a decent amount of experience in conventional circuit design and microcontroller programming. The circuits here are not particularly challenging, outside of the feed point with the antenna.

The gold leaf could present a challenge, but DuoSkin reported it as relatively durable with sufficient trace widths. If it isn’t working for some reason, other conductive tape or material could be attempted.

As a bare minimum, I expect to at least duplicate the results gathered by MIT in their DuoSkin study. Part of the aim of that paper was the technical ease at which circuits like these could be created, so I don’t anticipate duplication taking longer than the two months that we have.