WearableCircuits

WearableCircuits

John Compas

Exploring the possibilities of wearable circuitry with and without power sources

Higher quality PNG: https://drive.google.com/file/d/1DKPj96yx_M83p9iTGX71fJsnb3ftzoNc/view?usp=sharing

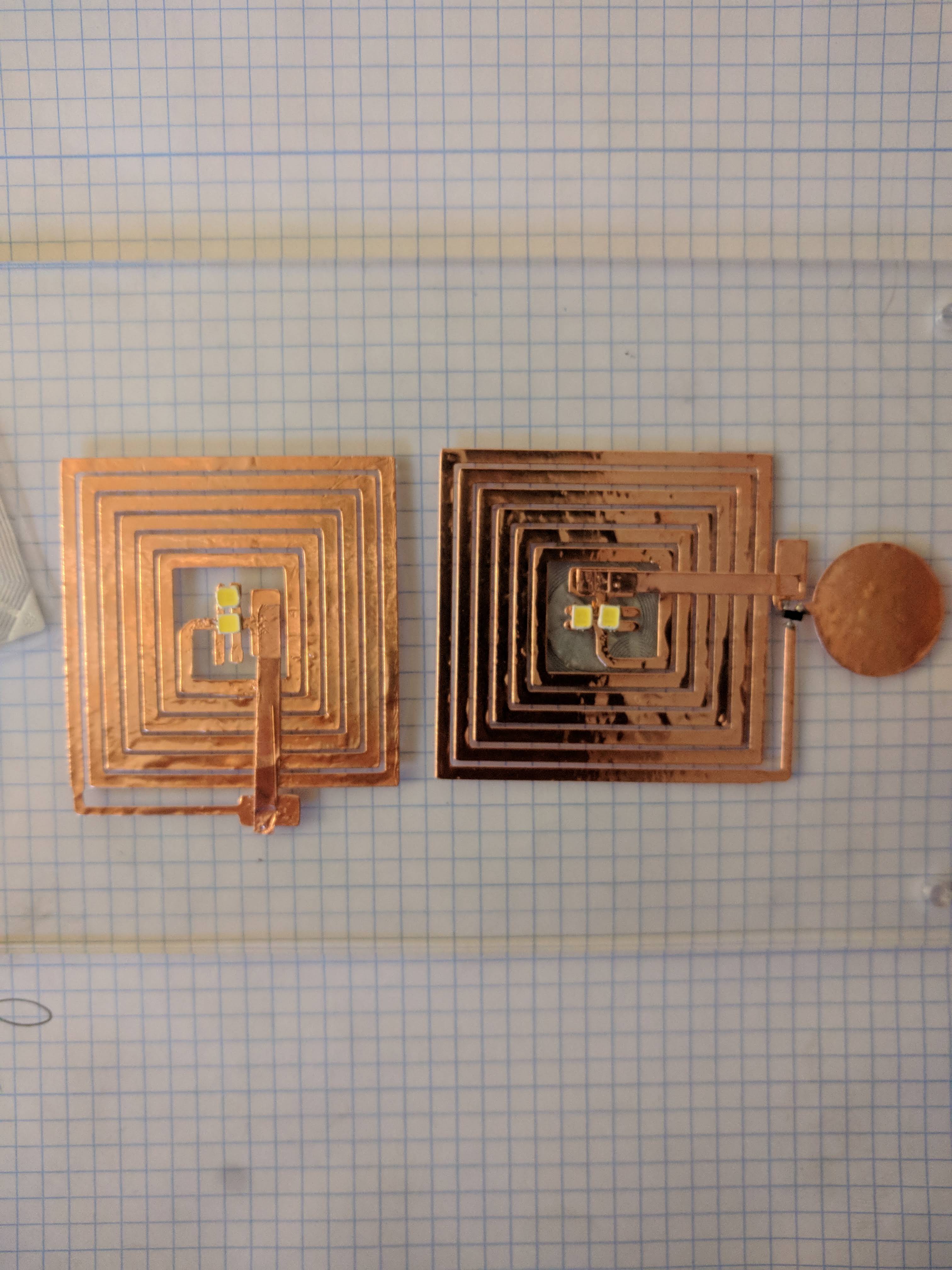

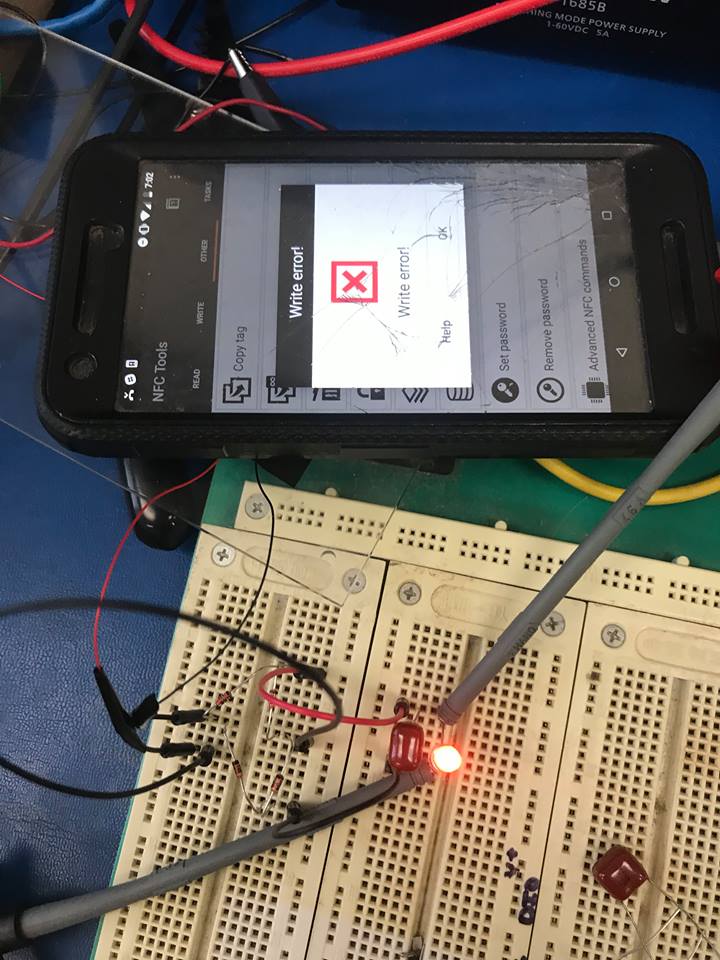

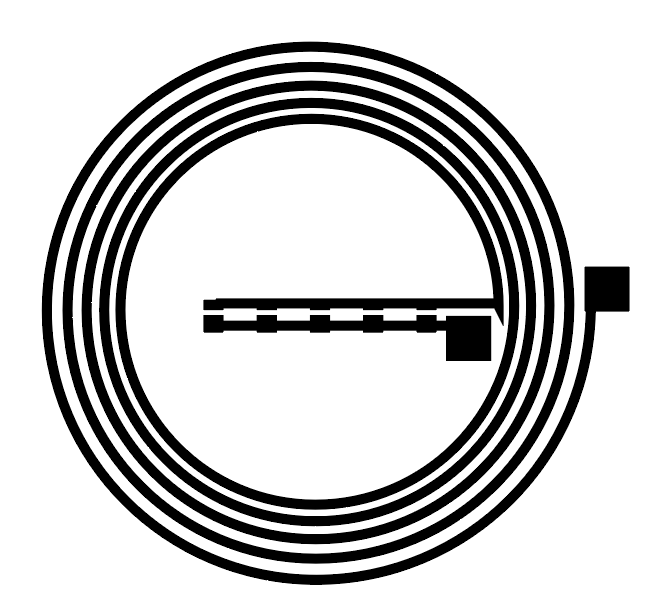

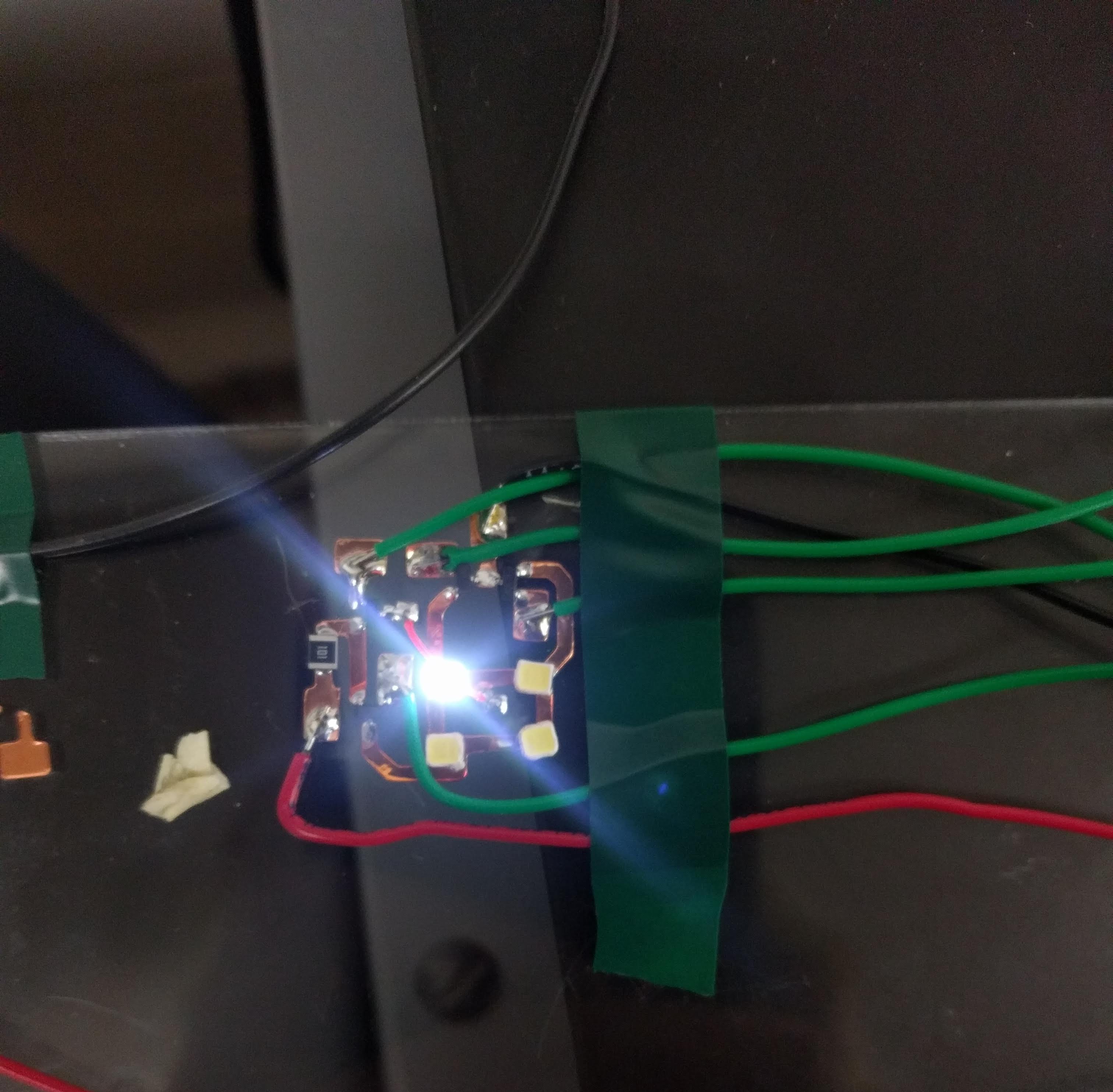

My project is an NFC coil, constructed out of copper foil, that powers devices or LEDs off of a phone or other NFC reader/writer. It is essentially an air-cored transformer, as the coil in the phone creates a magnetic field with alternating intensity. This time-varying magnetic field, due to Faraday’s Law, creates a voltage potential over the coil. This voltage potential can be used to power very-low-power devices such as an LED or (if rectified) microcontrollers. I stuck to using LEDs for this project because of their ease of use and visual demonstration.

I’m pretty pleased the NFC power works as well as it does, especially with many Android phones that everyone has in their pockets. I would have liked the “powerable” distance to be larger, but per the NFC specifications of <10cm my device performs about as well as commercial ones.

The fact that the LEDs work so well is great. I was guestimating the design of my NFC coil, trying to estimate the inductance I needed. The coil generates ~3.5Vpp when close to a phone and the current produced was on average about 10mA. This gives about 17mW of power. Whether the LEDs would work was up in the air until I tested them.

I accomplished my goal of a remotely powered, wearable circuit. I wasn’t able to get knee deep into the antenna design needed for higher frequency RFID but that would have taken a considerable amount of time and could have been almost impossible.

I didn’t wind up having the time to do any sensor design. I realize that programming my own sensors would have taken a serious amount of time and money. The common RFID / NFC sensors need some sort of devboard or breakout board to be programmable. Figuring out their firmware would have been another massive hurdle.

The largest challenge was getting the vinyl cutter to cooperate and not tear up the copper when cutting. It would also sometimes not complete edges or cut quite right.

Through trial and error, I started laminating the copper with a layer of vinyl to protect it. This stopped the cutter from tearing up the surface of the copper. The issues with the cutter not complete edges was a little more persistent. I eventually figured out that small details were (mostly) the cause. Any small corner or other detail in my SVG file could cause the cutter trouble. I took to simplify my SVGs before cutting them.

This mostly solved the issue, but there were still some times when I had to use an Exacto knife to weed part of the circuit.

I would put a lot of effort into getting my hands on some of that Lumilor paint. I potentially would see if I could get the Makerspace or another organization to sponsor purchasing it. I think it could be really interesting in combination with coils that generate induced AC voltage. Finally, I would try to design my own NFC “power” output PCB that would have increased and variable output for testing.

- Clear Covering Self-Adhesive

- https://www.amazon.com/Magic-Cover-Adhesive-Contact-Projects/dp/B000BPF9QY/ref=sr_1_26?crid=QOW16D2H82TC&keywords=vinyl+adhesive+paper&qid=1551742619&s=gateway&sprefix=vinyl+ad%2Caps%2C195&sr=8-26

- Count: 1

- Cost: $5.50

- Silhouette Temporary Tattoo Paper

- https://www.amazon.com/Silhouette-MEDIA-TATTOO-Temporary-Tattoo-Paper/dp/B0043WJ3OA

- Count: 1

- Cost: $8.99

- Spray Adhesive

- https://www.amazon.com/3M-General-Purpose-45-Adhesive/dp/B000PCWRMC

- Count: 1

- Cost: $5.77

- SPMWH22286D5WAP0S2 (Samsung LEDs)

- Count: 100

- Cost: $1.29

- Conductive Guitar Tape

- Count: 1

- Cost: $5.60

- Copper Foil Tape

- Count: 1

- $4.49